As juntas isoladas dos trilhos funcionam como o sistema nervoso central das linhas ferroviárias, impedindo que a corrente elétrica flua entre as extremidades de dois trilhos adjacentes.

Quando um trem passa por uma junta, as rodas do trem completam o circuito elétrico, permitindo que os operadores ferroviários saibam a localização exata dos trens em ferrovias complexas e acionando sinais de cruzamento quando um trem se aproxima de um cruzamento de estrada.

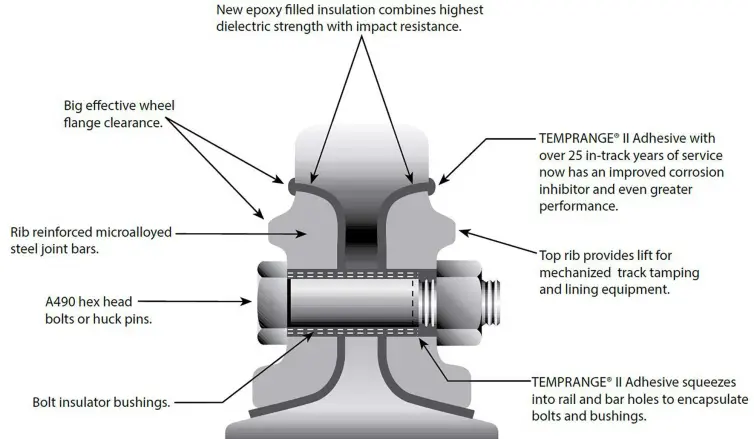

No processo de fabricação, os membros da equipe da L.B. Foster recebem peças de trilho de aço de 80 pés, cortam-nas ao meio e criam uma descontinuidade elétrica colocando um material isolante (Kevlar®) entre as duas metades. Em seguida, eles reforçam a junção adicionando uma barra de suporte e prendem todos os componentes no lugar com epóxi.

Montado na fábrica:

Colado com epóxi TEMPRANGE® II de alta integridade para longa vida útil

Barra de junta de micro liga de contato total

Montado no comprimento especificado, até 60' de comprimento

Disponível em configurações de trilho desgastado/trilho de transição

Montado com parafusos A-490 ou pinos de articulação (6 ou 8)

ENDURA-JOINT® de vida ultra longa com isolamento de aramida também disponível

KEVLAR® é uma marca registrada da E. I. du Pont de Nemours and Company ou de suas afiliadas.

A ilustração do produto mostra os recursos de nossos conjuntos de juntas isoladas coladas.

Pedidos e mais informações

Para saber mais sobre esse produto, preencha nosso breve formulário de contato para entrar em contato com nossa equipe de especialistas.

Entre em contato com a L.B. Foster Representantes regionais