Improving quality

- Feb 19, 2019

- Rail

A major production quality concern for advanced component manufacturers is the issue of foreign materials left inside precision castings. Alex Morgan explains how our Automation & Materials Handling team created an innovative, automated cleaning solution.

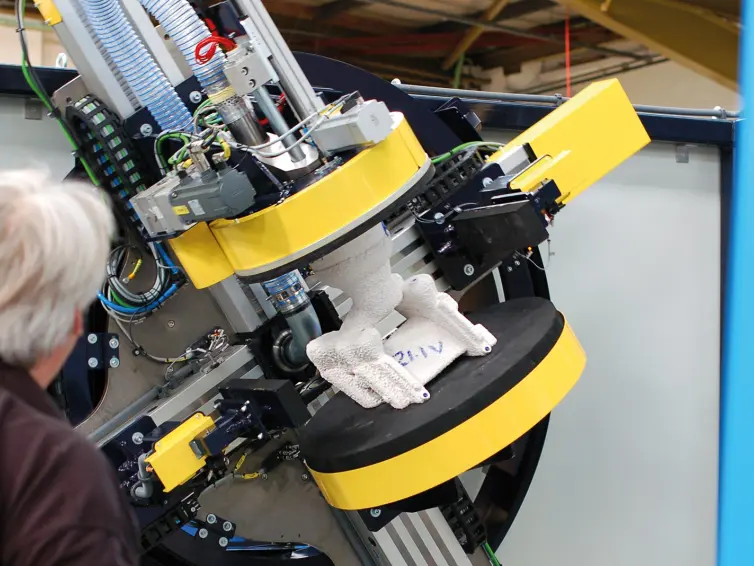

An advanced engineering component manufacturer based in Leeds approached us to come up with a smart ceramic mould cleaning solution to aid the removal of foreign materials from ceramic aerofoil casts. Our design team quickly got to work fashioning an innovative fabricated machine, housing a rotating frame with clamps to securely hold ceramic casts across a range of sizes. A powerful vacuum system is then used to transport foreign materials out of the casts. Where our solution really stands out is the inclusion of a sophisticated vision system. This performs a particle check of the foreign material collected in the filter, prior to returning the cast to the production line.

Our automated mould cleaning machine allows the company to fine-tune programs, providing flexibility, plus a range of tools, to remove all foreign particles. The ceramic part clamps, rotation mechanism, vacuum system and vision system are all housed in a mild steel machine frame.

A customer spokesperson adds: “The issue of casting imperfections is a production challenge for all precision component manufacturers. Left unchecked, castings end up with inclusions, leading to rework and scrap and associated costs and lost time.

The solution that the team at L.B. Foster Automation & Materials Handling designed demonstrated a high level of innovation and pragmatism. It’s not overdesigned and how it cleans the moulds is simple, but it’s the combination of features and benefits that make it a highly effective solution.