Elephant & Castle Station - Fire Detection Services

- Jun 30, 2022

- Rail

Elephant & Castle station is located in the Elephant and Castle area of Newington in the London Borough of Southwark. The station is on the Bank branch of the Northern Line between Kennington and Borough stations, and is the southern terminus of the Bakerloo line and accommodates almost 20 million passengers each year.

Lifts at the Northern line entrance to Elephant & Castle Tube station were closed during peak times in the first half of 2021 to replace the doors and other associated parts of the lifts and to install a new fire detection system in the lift shaft as part of Transport for London’s “commitment to increasing safety”.

L.B. Foster Telecoms (TEW Plus Ltd) was subcontracted by principal contractor Brookvex, one of the UK’s leading specialists in multi-disciplinary infrastructure and technical services, to install fire detection services as part of the lift upgrade project.

Requirement

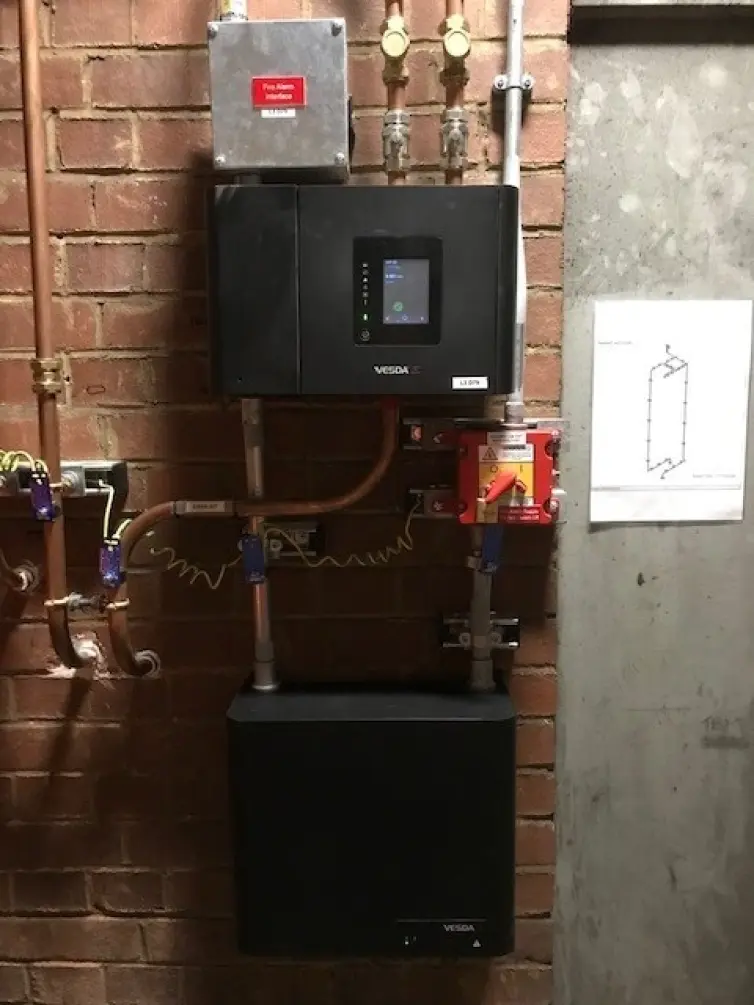

The works at Elephant & Castle station were part of Transport for London’s ‘Lift Replacement Project’. These included the installation of a new Class C Aspirating Smoke Detector (ASD) System, installed to BS 5839-1 2017 Fire detection and fire alarm systems for buildings – Part 1: Code of practice for design, installation, commissioning and maintenance of systems in non-domestic premises. The new system provides complete coverage of the entire shaft length of Lifts 5 and 6, plus the installation of lift interfaces between the Station Fire System and the new Lift Control Equipment.

Health & Safety

L.B. Foster Telecoms (TEW Plus) is committed to the highest standards of health and safety for our people and the contractors with which we work. The rail network is a hazardous place and we comply with London Underground’s Contract Standard S 1552 (QUENSH). We worked in collaboration with the principal contractor to achieve this, ensuring works were conducted in accordance with relevant policies and procedures. This includes:

Ensuring our staff carried up to date Sentinel Cards

Providing a qualified and experienced site person in charge to supervise staff and ensure the site was set up correctly

Undertaking drug and alcohol testing in compliance with London Underground’s requirements

Taking part in daily site briefings with the principal contractor and collaborating with other contractors’ operatives

Using site specific risk assessments, method statement and work plans

Maintaining accurate records of site attendance by operatives

Checking operatives wear full PPE correctly.

Our Solution

L.B. Foster Telecoms (TEW Plus Ltd) worked with principal contractor Brookvex, and Transport for London to design, install and commission a new Aspirating Smoke Detector (ASD) System, as part of the Lift Replacement Project.

The installed system is commissioned to Class C sensitivity, with power provided by a double pole isolator. Sampling pipes cover the top of the lift shafts, providing vertical sampling in opposite corners of the shafts, as well as coverage of draught relief inlets and outlets. Vertical sampling holes are installed approximately four to five metres apart. The lowest sampling point is level with the top of the train at the lower landing.

Test Points comprise full bore isolation valves with end caps. A full bore isolating valve and adjacent purging facility is installed on all sampling pipes above the ASD panel. Sampling points are located to coincide with computer modelling in accordance with Smoke Detection Criteria C and in compliance with EN54 Part 20. Pipe transit time is designed not to exceed 120 seconds (the transit time is measured from when the smoke enters the further sampling point to the first reaction in ASD control panel). The system operating time from the point of smoke testing to full evacuation does not exceed 180 seconds.

The Installation follows the guidelines of FEGN 19 (Fire Engineering Guidance Notice). Cold smoke pellet tests were used during the witness test/return to service visit. Two tests were carried out with a TfL fire engineer witnessing one test to prove all areas of the shaft are sufficiently covered. The additional test demonstrated that the system is ready to RTS.

The system exhaust is vented into the same area of detection. This ensures that the system is balanced and reduces the piston effect on the equipment created by the movement of the lifts. The pipe drops down the shaft by at least 2m with the open end facing downwards. All necessary cables, connectors etc interface the ASD Control Panel with the station fire system. A CHQ-PCM unit reports fire and fault signals back to the station fire system. A new CHQ-DRC interface unit provides lift recall. Programming and commissioning of the installation was carried out by the L.B. Foster engineers who have received comprehensive training from the manufacturer with respect to design and commissioning.

“What we look for in any project is expert advice and guidance. The team at L.B. Foster Telecoms (TEW Plus) delivered on all counts, offering experience and expertise that meant the final installed solution achieved exactly what was needed. What shone through was the team’s inherent understanding of the project’s challenges and an ability to identify great solutions.”