We combine our state-of-the-art wheel/rail interface rail lubrication testing facility, with rigorous scientific analysis and on-track field testing to bring you the next generation of gauge face greases and advanced application equipment technologies.

We combine our state-of-the-art wheel/rail interface rail lubrication testing facility, with rigorous scientific analysis and on-track field testing to bring you the next generation of gauge face greases and advanced application equipment technologies.

This pursuit of excellence highlights our core objective of providing our customers with the world’s most advanced friction management products that will consistently and reliably protect the wheel / rail interface.

Recognized globally as the experts in railroad friction management, we continue to develop innovative products that:

Reduce rail and wheel wear

Reduce lateral forces

Reduce derailment potential

Reduce energy consumption

Reduce Rolling Contact Fatigue (RCF) development

SYNCURVE®'s all-season adaptability and biodegradable formulation make it a highly sustainable solution, perfect for improving rail performance while aligning with environmental goals.

Rail Gauge Face Greases

Our gauge face grease portfolio starts with SYNCURVE and SYNCURVE Transit, exceedingly durable all-season rail curve lubricants giving the customer flexibility of either employing a lower application rate for existing spaced lubricators (up to 50% lower) or increasing lubricator spacing using current application rates.

SYNCURVE and SYNCURVE Transit provide excellent protection in the wheel flange/gauge face interface, they are biodegradable, and contribute to improved fuel economy.

We also provide a full range of high-performance and environmentally friendly rail lubricants including:

DURACURVE® PRO

Enhanced Durability and Performance for Rail Curve Lubrication

A highly durable rail curve grease that has extended carry distances, excellent wear protection, and effectively reduces rail wear.

DURACURVE PRO has been formulated to optimize the pumpability, adhesion, and water resistance required in the wheel/rail environment, contributing to lower maintenance and operating costs. DURACURVE PRO is currently available in a summer grade.

ALLCURVE®

Versatile All-Season Rail lubrication for Simplified Inventory Management

A cost-effective all-season petroleum grease that meets adhesion, pumpability, and load-carrying requirements at all operating temperatures.

ALLCURVE eliminates the need to inventory both summer and winter grades as part of your rail lubrication program, further reducing maintenance costs.

BIOCURVE® LB2

Environmentally Friendly, All-Season Biodegradable Rail Grease

A premium quality readily biodegradable rail curve grease formulated with vegetable oils. BIOCURVE LB2 has exceptional product stability and lower propensity for bar clogging compared to other biodegradable greases.

This product is recommended for locations requiring the highest level of biodegradability, such as near waterways or other environmentally sensitive areas.

BIOCURVE LB2 is an all-season product suitable for year-round use in all climates, ensuring operational efficiency and reduced operating costs.

DURACURVE® CE

Economical Solution for Effective Rail Preservation and Weather Resistance

A grease specifically designed to ensure good wear resistance, effective weatherproofing, and efficient carry-down at an economical cost.

DURACURVE CE is currently available in a summer grade, offering a cost-effective solution for maintaining railroad grease systems and extending the life of railway equipment.

Ordering and More Information

Learn more about this product, complete our short contact form to connect with our expert team.

Rail Lubrication Equipment

PROTECTOR® Application Systems

Our next generation PROTECTOR X trackside friction management systems include heavily sloped product compartment with the industry’s lowest cavitation levels and true first-in, first-out product utilization.

These new systems allow for longer intervals between tank refills, easier product transitions between seasons, and less track access time required for maintenance.

The Most Advanced Friction Management System Available in the World

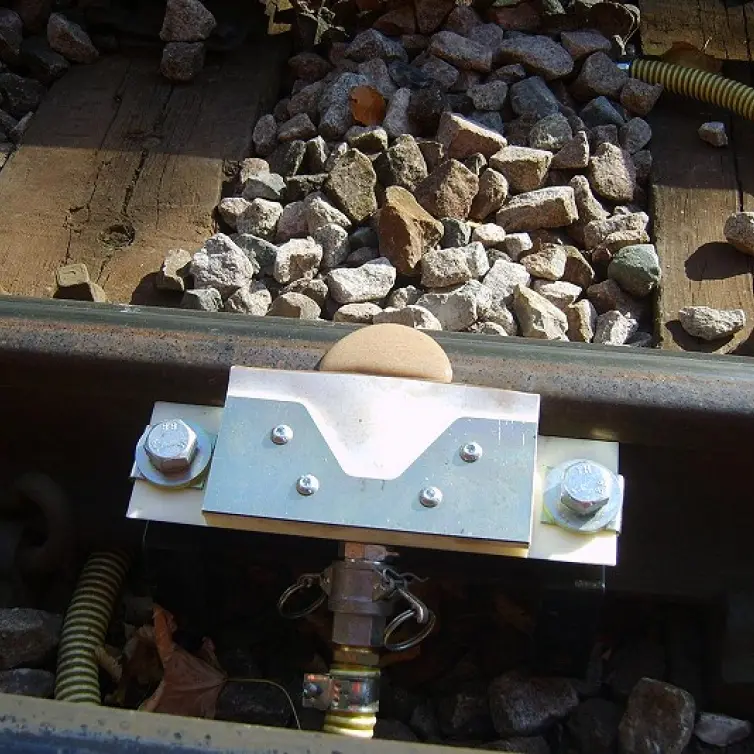

Combined with our MC-4XL® or MC-5® application bars with GREASEGUIDES® and our next generation Remote Performance Monitoring (RPM), the PROTECTOR system is the most advanced friction management system available in the world.

MC-4XL (long length) and MC-5 (short length) applicator bars accurately deliver lubricant to wheel flanges / rail gauge face.

These two bars share our industry-leading channel and port design, providing equal and reliable delivery of lubrication to each port, preventing clogs and reducing friction .

L.B. Foster’s patented GREASEGUIDE troughs re-direct and guide grease back to the wheel flange where it can carry out its intended purpose — protecting the rail and wheels.

GREASEGUIDE technology helps to improve lubricant pick-up, thereby increasing carry-down and reducing waste.

Friction Management Experts

Built on over 40+ years of in-service experience and continuous technological innovation, L.B. Foster PROTECTOR systems are known to be:

Exceedingly reliable

Easy to maintain

Consistent and precise in their application rate. Our innovative control system uses proprietary compensation algorithms to seamlessly adapt to changing operating conditions and consistently outputs the correct amount of lubrication.

Our Gauge Face Lubrication Product Portfolio

Whatever your gauge face lubrication challenge, we can help. On top of the products showcased above, we offer:

Our legacy PROTECTOR IV electric application systems

PW and 761 hydraulic application systems

Ordering and More Information

Learn more about this product, complete our short contact form to connect with our expert team.

Contact L.B. Foster Regional Representatives