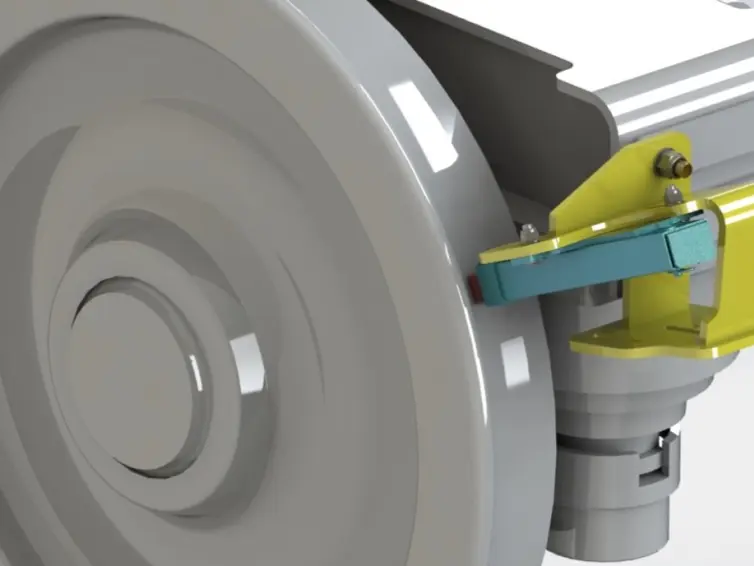

Kelsan® wheel tread friction modifier solid sticks provide a micron-thick ‘thin film’ layer between the wheel tread and the top of the rail. This provides an intermediate friction level on the wheel and rail interface of the rail system.

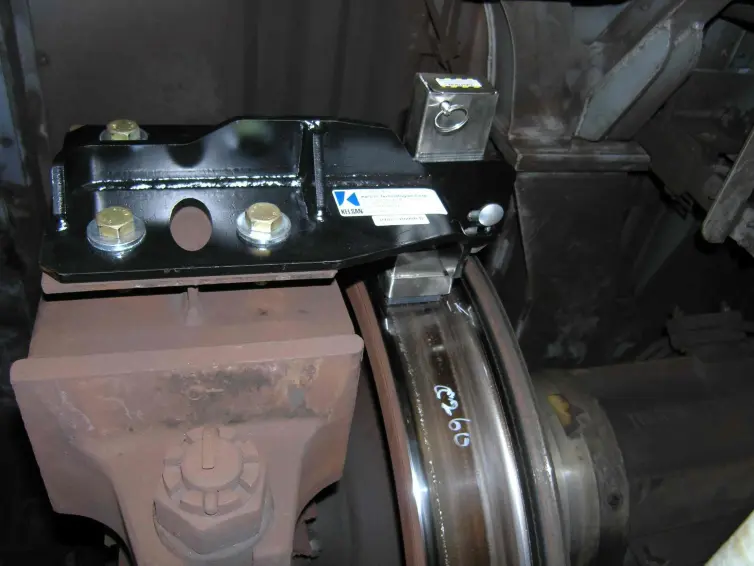

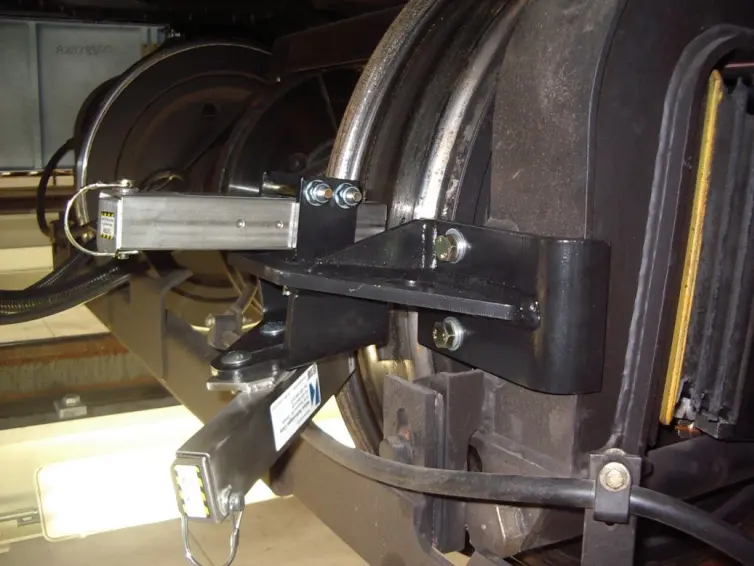

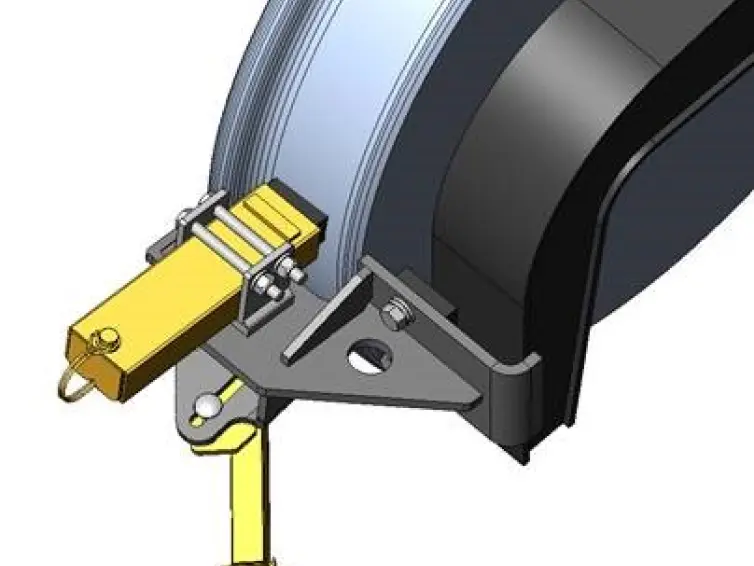

The tread sticks are applied using a spring-loaded bracket and applicator assembly, specifically designed and built for each customer. The bracket and applicator assembly is attached to the bogie frame of the rail vehicle.

Benefits of solid tread friction modifier sticks:

Extends wheel tread and top of rail life

Reduces short pitch rail corrugations

No effect on traction or braking

Consistent application to train fleet and throughout the rail system

Reduces lateral forces and energy consumption

Clean and environmentally friendly solution

No reduction in performance at high speeds

Wheel Tread Friction Management

With over 25 years of proven performance in the field, L.B. Foster’s KELSAN® HPF and SFM are the best-selling solid stick friction modifiers in the world today. KELSAN HPF and SFM are premium solid materials that provide an intermediate coefficient of friction. The products are an engineered composite of solid friction modifying materials bound together by a thermosetting resin that provides excellent protection to wheel treads. Further benefits for KELSAN HPF and SFM are:

Thermal stability ensures no product migration

Patented interlocking feature to ensure continuous application and minimal stick wastage

Non-toxic

Non-flammable and flame resistant

Custom System and Hardware Design

Wheel tread friction modifier solid sticks are applied via a vehicle-mounted spring-loaded applicator and bracket assembly, specifically designed and built for each customer. The bracket and applicator assembly are attached to the bogie frame of the rail vehicle. The hardware is designed and / or tested to meet each customer’s shock and vibration standards.

With over 25 years of experience implementing wheel tread friction management programs, L.B. Foster can work with you to determine the coverage and train configuration for your system and tread wear targets.

Ordering and More Information

Learn more about this product, complete our short contact form to connect with our expert team.

Contact L.B. Foster Regional Representatives