Acoustic robotic spray cell from L.B. Foster

- Aug 11, 2020

- Rail

Thermal spraying is a technology which improves or restores the surface of a solid material. It is used widely in the aviation industry to apply metal coatings that provide improved fatigue resistance, protection against wear and tear and improved impact and corrosion protection for specialised engineering components, such as aircraft wings.

Requirement

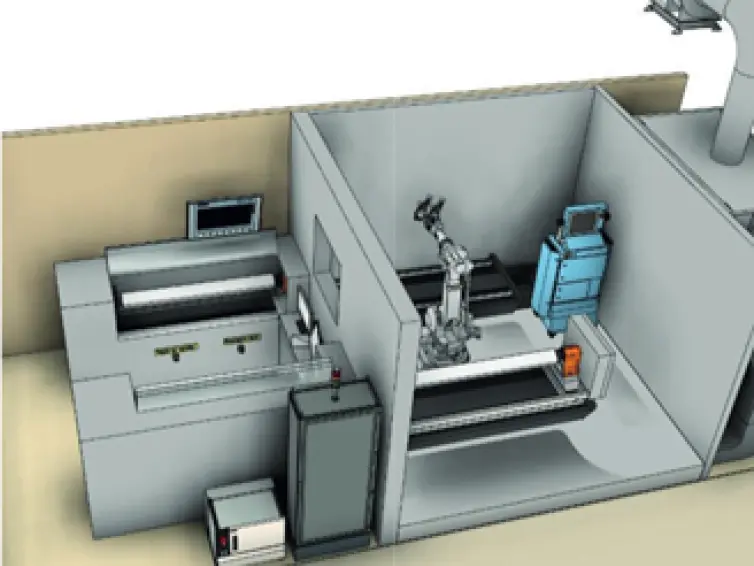

L.B. Foster Automation & Materials Handling was invited to tender to develop an autonomous robotic spray cell by a world leader in metaliisation application technologies and processes. The self-contained spray cell houses spray technology that applies specialised metallised coatings to protect the leading substrate edge on aircraft wings, with the flexibility to apply coatings to three wing design variants. The spray cell comprises:

Acoustic booth

Linear transfer system

Safety circuit

Extraction system

False floor in acoustic area

The metallisation process emits highly toxic gases, which need to be safely captured and extracted to protect operators. Airflow is managed by an integrated smart control panel designed and manufactured by L.B. Foster’s expert team

Specification

Acoustic booth

1.5mm mild steel outer panel, 15mm sound board,

80mm thick rockwool with flexible membrane and 1.5mm perforated sheet

Powder coated finish

Double doors with 500x500 tinted viewing windows

1 x 600x600 tinted viewing window

2 x 2500mm wide x 1000mm high x 600mm deep high exhaust hoods

2 x sound attenuated air inlets

Linear transfer system

ABB IRB L-300 rotation unit

Metal substrates including manual clamps

BAHR Type QSZ80 actuator with a planetary gearbox and siemens servo drive

Ergonomic steel frame

2 x sound attenuated transfer panels

2 x screens for measuring of the component resistance

1 x screen for Prodigy readout and spray system monitoring

Extraction system

ABB IRB L-300 rotation unit

RPC 24/23.5 Reverse Jet Filtration Unit supplied with

24x 23.5m² non-woven polyester filter cartridges

Pre-separation chamber

Reverse jet cleaning system

Compressed air filter regulator

Magnehelic pressure differential gauge

Discharge hopper with 110 litre dust collection bins

Reinforced mild steel construction

Weight – 3500kg across four point loads

1 x CM9 – 500R9 centrifugal fan unit with discharge silencer

Fan duty - 12,500m³/hr @ 300mm wg

Motor power - 15kw, 415v 3ph 50Hz

Weight - 750kg across four point loads

Our solution

L.B. Foster Automation & Materials Handling designed, manufactured, tested and commission the new acoustic robotic spray cell at its Automation ‘Centre of Excllence’ in Nottingham.

Central to our solution was securing the health and safety of operatives. This involved ensuring that the design and manufacture addressed the joint issues of noise suppression and booth integrity against gas leaks.

The linear transfer system which moves the wing substrates into and out of the spray cell is built on a shrouded ergonomic steel frame with an interlocking door. This allows movement of the shuttle only when it is safe to do so. The door also serves as a secondary barrier against sound generated in the process room. The shuttles feature two sound attenuated transfer panels on either end to ensure that acoustic booth remains ‘sealed’ when the operator is loading and unloading.

Two screens above each component station allow for measuring of the component resistance during the final spray operations.

An additional screen is used for readout and spray system monitoring, with an integral inspection window in the operator’s area.

The level of the floor of the spray room is raised to allow for the air extraction to be taken out from the bottom of the extraction hoods under the positioners. This reduces the amount of clutter and hazards within the booth from a maintenance perspective.

The motor for the extraction system is placed on the roof of the building. This helps reduce the noise of the extractor within the main building and reduces the noise of the booth in general.

What they said

“As leading experts worldwide in the supply and support of advanced, innovative surface coating technology we have a very stringent selection process for our technology partners. L.B. Foster’s proven track record of success in automated manufacturing provided us with the confidence to progress on this project.”

“The solution that the team created does exactly what it says on the tin, and more. The experience expertise that L.B. Foster brings to the table enables them to make valid suggestions that improve the end solution.”